Trenton Engine was built in 1951 to make high-volume V8s; today, it makes V6 engines and motor parts. Nearly a quarter of a century ago, the plant was just about at its capacity, as Chrysler had been building up its sales through the 1990s and dropping imported Mitsubishi fours and sixes. They made aluminum-block V6 engines for cars; iron-block engines for minivans; and Neon four-cylinders, as well as the pistons, rods, cranks, cams, blocks, heads, manifolds, and water pumps. They even made parts for the LA-series engines assembled at Mound Road.

As 1999 progressed, Daimler’s takeover, begun in 1998, as moved forward, and they started outsourcing parts to other companies and moved the 3.5 engines to Kenosha. That made enough to make room for two new lines, Department 838 and 724.

One of the new lines replaced an older one which machined cylinder heads. The other was meant for making minivan 3.5 liter V6 engines; about a week before it was to start production, executives shut it down, fearing customer confusion.

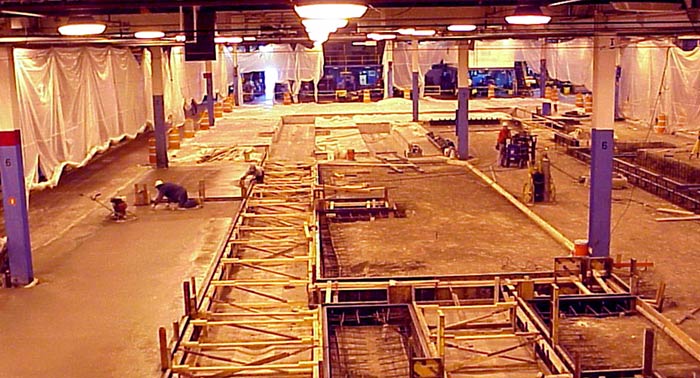

These photos, taken from Motales.com and provided by Dave Van Buren, show how it was done—including digging holes in the existing concrete floor, then pouring new concrete as needed.

For the full story and many more photos, see motales.com.